project summary

Permanent & Temporary Offices

category

location

Southwestern U.S.A.

Sunbelt facility

Northwest Building Systems A Sunbelt Company

size

4620 Sq Ft

key achievements

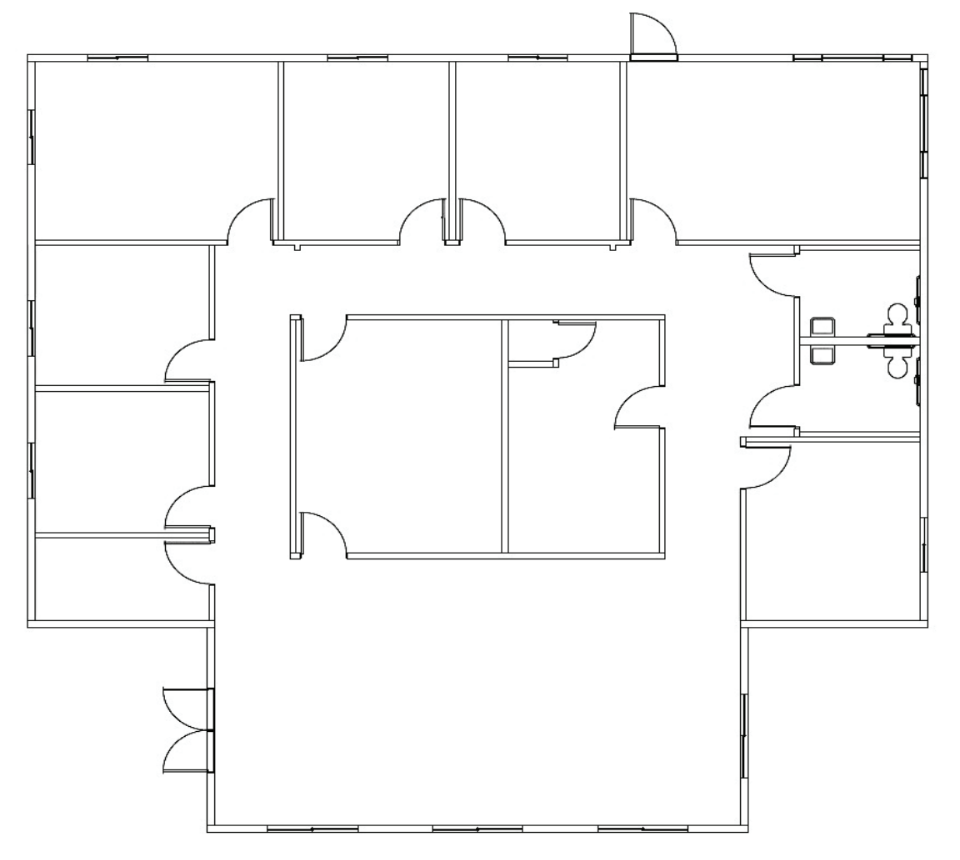

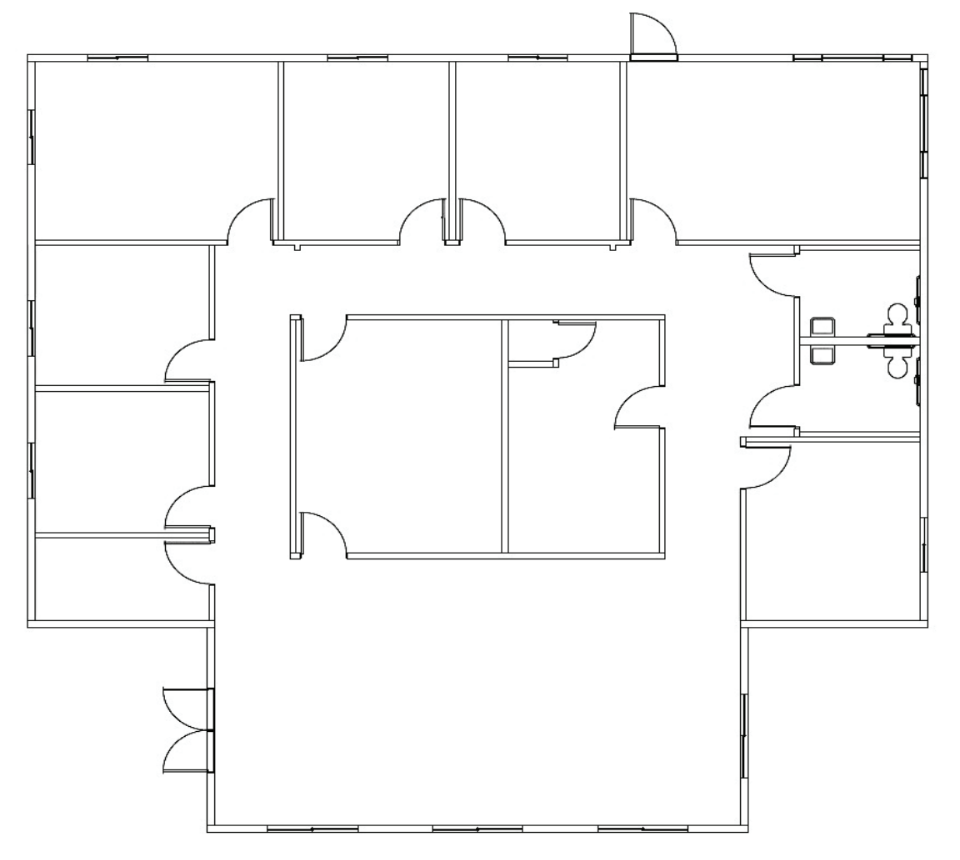

Building Floor Plan Highlights

case study summary

Atlas Sand and Rock needed a new administrative building to support operations and retail customers. Prioritizing speed and cost efficiency, they chose modular construction. Northwest Building Systems partnered with Pacific Mobile Structures to provide this project after demolishing the old office.

The solution included a 4,620-square-foot permanent modular building (57’ x 60’) and two temporary relocatable units (12’ x 56’ and 12’ x 44’) used during construction. One of the temporary buildings was later repurposed by Atlas for another site. Installation took place at the former quarry site, with Pacific Mobile handling final site work, interior finishes, and on-site roof construction—completed just before a major rainstorm.

The permanent structure features oversized windows with views of truck traffic, a spacious retail area with storage, a conference room, and a U-shaped counter for truck drivers. Additional amenities include mini-split HVAC systems, two ADA-compliant restrooms, 9-foot ceilings, upgraded board and batten siding, carpet in carbon tones, and storefront entry doors.

The project was a success thanks to strong communication and a seamless first-time partnership between Atlas Sand and Rock and Pacific Mobile Structures—delivering a modern, efficient facility built to last.

key achievements

Building Floor Plan Highlights

case study summary

Atlas Sand and Rock needed a new administrative building to support operations and retail customers. Prioritizing speed and cost efficiency, they chose modular construction. Northwest Building Systems partnered with Pacific Mobile Structures to provide this project after demolishing the old office.

The solution included a 4,620-square-foot permanent modular building (57’ x 60’) and two temporary relocatable units (12’ x 56’ and 12’ x 44’) used during construction. One of the temporary buildings was later repurposed by Atlas for another site. Installation took place at the former quarry site, with Pacific Mobile handling final site work, interior finishes, and on-site roof construction—completed just before a major rainstorm.

The permanent structure features oversized windows with views of truck traffic, a spacious retail area with storage, a conference room, and a U-shaped counter for truck drivers. Additional amenities include mini-split HVAC systems, two ADA-compliant restrooms, 9-foot ceilings, upgraded board and batten siding, carpet in carbon tones, and storefront entry doors.

The project was a success thanks to strong communication and a seamless first-time partnership between Atlas Sand and Rock and Pacific Mobile Structures—delivering a modern, efficient facility built to last.