project summary

Radiotherapy/Medical Clinic & Office Space

category

location

Coastal U.S.A.

Sunbelt facility

Whitley Manufacturing A Sunbelt Company

size

16,000 sq. ft.

key achievements

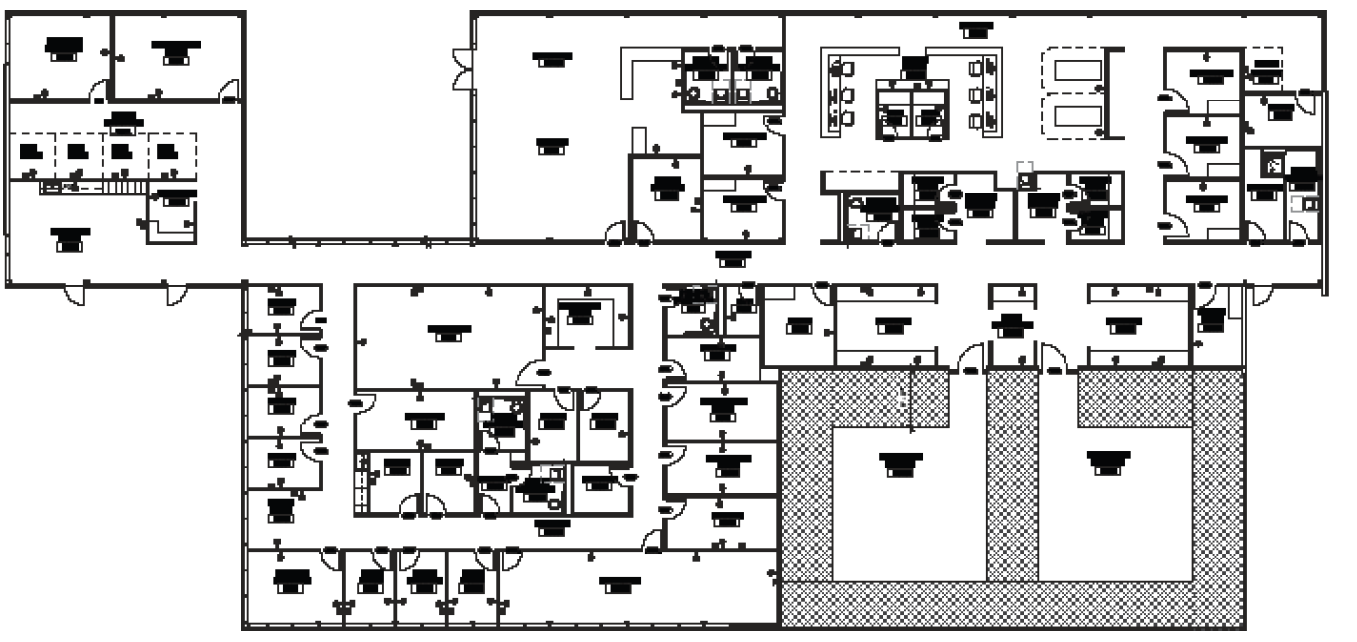

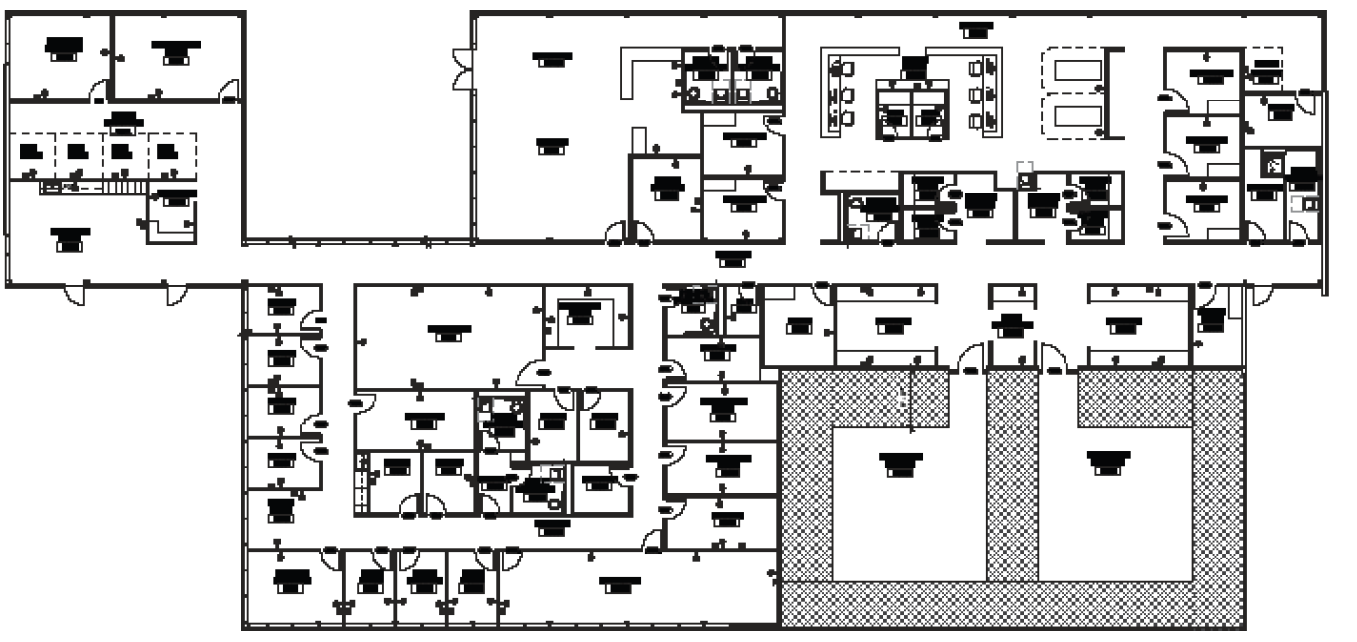

Building Floor Plan Highlights

case study summary

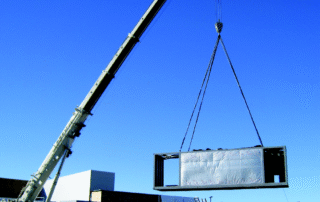

The Cancer Center was expanded with a state-of-the-art radiotherapy facility that could house a new linear accelerator and advanced treatment technology. The goal was to create a high-performance clinical and office environment with minimal construction disruption and maximum precision.

Whitley Manufacturing, A Sunbelt Company, in partnership with a Sunbelt Modular Dealer, delivered a 16,000 sq. ft. modular medical facility designed to meet the demanding technical and regulatory standards of modern cancer treatment. The project included a radiotherapy vault, clinical suites, and administrative offices — all built using custom steel framing and proprietary radiation shielding methods

Constructed off-site and shipped across the country, the facility was completed in just seven months. By manufacturing the vault and clinical spaces concurrently with site preparation, the team achieved significant time and cost savings, while reducing waste and environmental impact.

key achievements

Building Floor Plan Highlights

case study summary

The Cancer Center was expanded with a state-of-the-art radiotherapy facility that could house a new linear accelerator and advanced treatment technology. The goal was to create a high-performance clinical and office environment with minimal construction disruption and maximum precision.

Whitley Manufacturing, A Sunbelt Company, in partnership with a Sunbelt Modular Dealer, delivered a 16,000 sq. ft. modular medical facility designed to meet the demanding technical and regulatory standards of modern cancer treatment. The project included a radiotherapy vault, clinical suites, and administrative offices — all built using custom steel framing and proprietary radiation shielding methods

Constructed off-site and shipped across the country, the facility was completed in just seven months. By manufacturing the vault and clinical spaces concurrently with site preparation, the team achieved significant time and cost savings, while reducing waste and environmental impact.