project summary

Relocatable Medical Clinic

category

location

Northwestern U.S.A.

Sunbelt facility

Whitley Manufacturing A Sunbelt Company

size

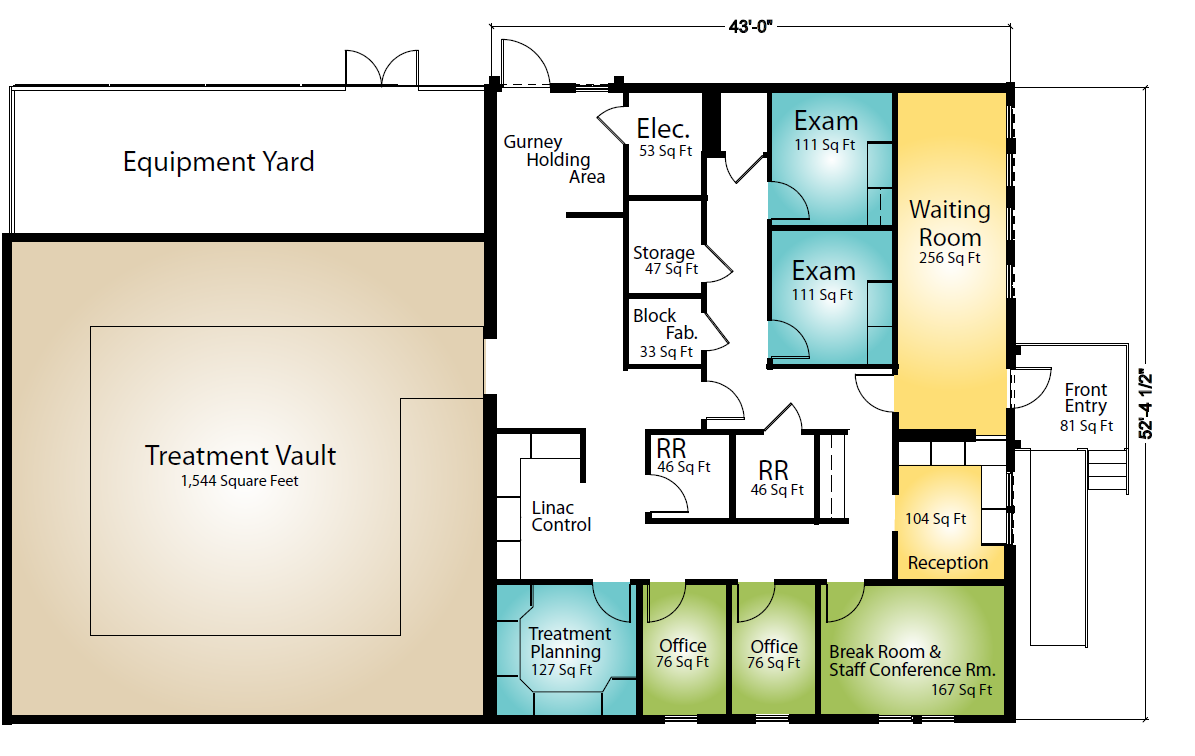

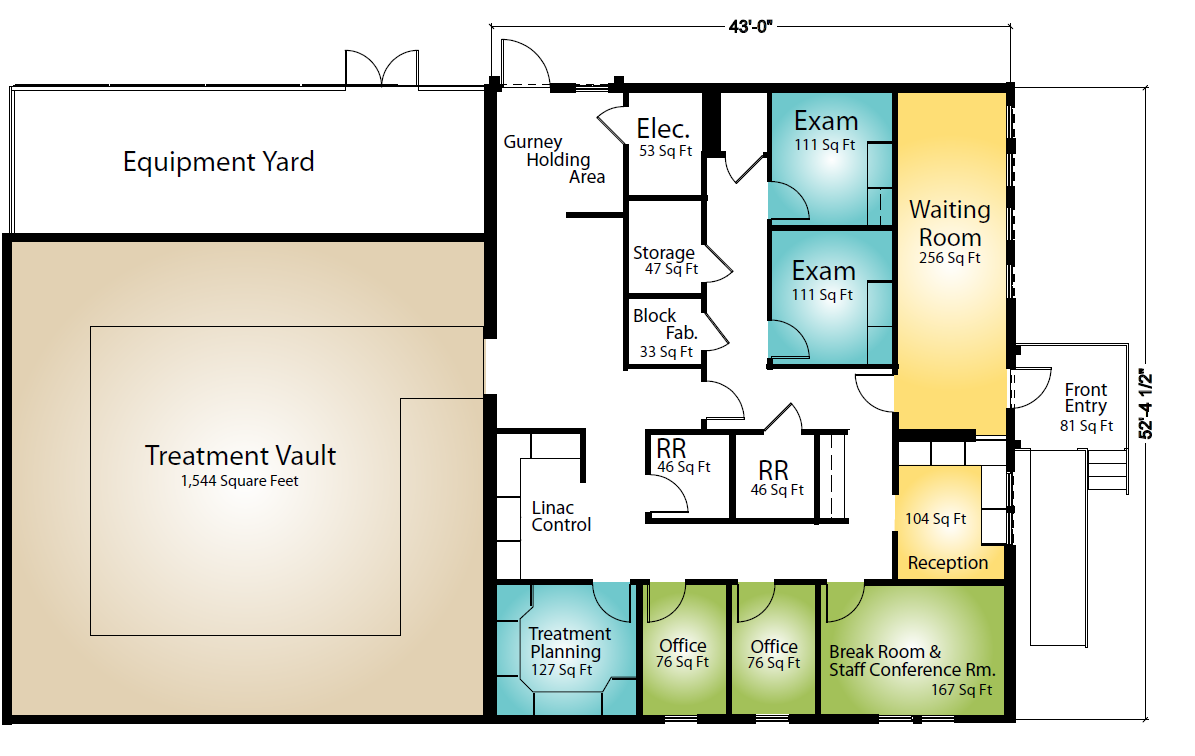

2,250 sq. ft. + 1,544 sq. ft. vault

Combined Building Floor Plan Highlights & Achievements

case study summary

A hospital in the Midwest sought to expand its oncology services with the latest in radiation treatment technology with a modular, turnkey radiotherapy solution pre-equipped with a Varian linear accelerator. The goal was to deliver advanced cancer treatment faster, safer, and more cost-effectively than traditional construction would allow.

Whitley Manufacturing, A Sunbelt Company, in partnership with A Sunbelt Modular Dealer delivered a 2,250 sq. ft. modular clinic and treatment vault, designed for rapid deployment and precision installation. The facility arrived with a pre-installed and pre-tested linear accelerator, allowing the hospital to begin patient treatments within weeks of delivery, rather than months.

Built to meet all health, state, and local codes, the center combines high-performance engineering with modern, professional aesthetics. Its modular design allows for future relocation, expansion, or technology upgrades, giving healthcare providers lasting flexibility and faster return on investment.

Building Floor Plan Highlights

case study summary

A hospital in the Midwest sought to expand its oncology services with the latest in radiation treatment technology with a modular, turnkey radiotherapy solution pre-equipped with a Varian linear accelerator. The goal was to deliver advanced cancer treatment faster, safer, and more cost-effectively than traditional construction would allow.

Whitley Manufacturing, A Sunbelt Company, in partnership with A Sunbelt Modular Dealer delivered a 2,250 sq. ft. modular clinic and treatment vault, designed for rapid deployment and precision installation. The facility arrived with a pre-installed and pre-tested linear accelerator, allowing the hospital to begin patient treatments within weeks of delivery, rather than months.

Built to meet all health, state, and local codes, the center combines high-performance engineering with modern, professional aesthetics. Its modular design allows for future relocation, expansion, or technology upgrades, giving healthcare providers lasting flexibility and faster return on investment.