project summary

Radiotherapy Clinic

category

location

Relocatable

Sunbelt facility

Whitley Manufacturing A Sunbelt Company

size

1,395 sq. ft.

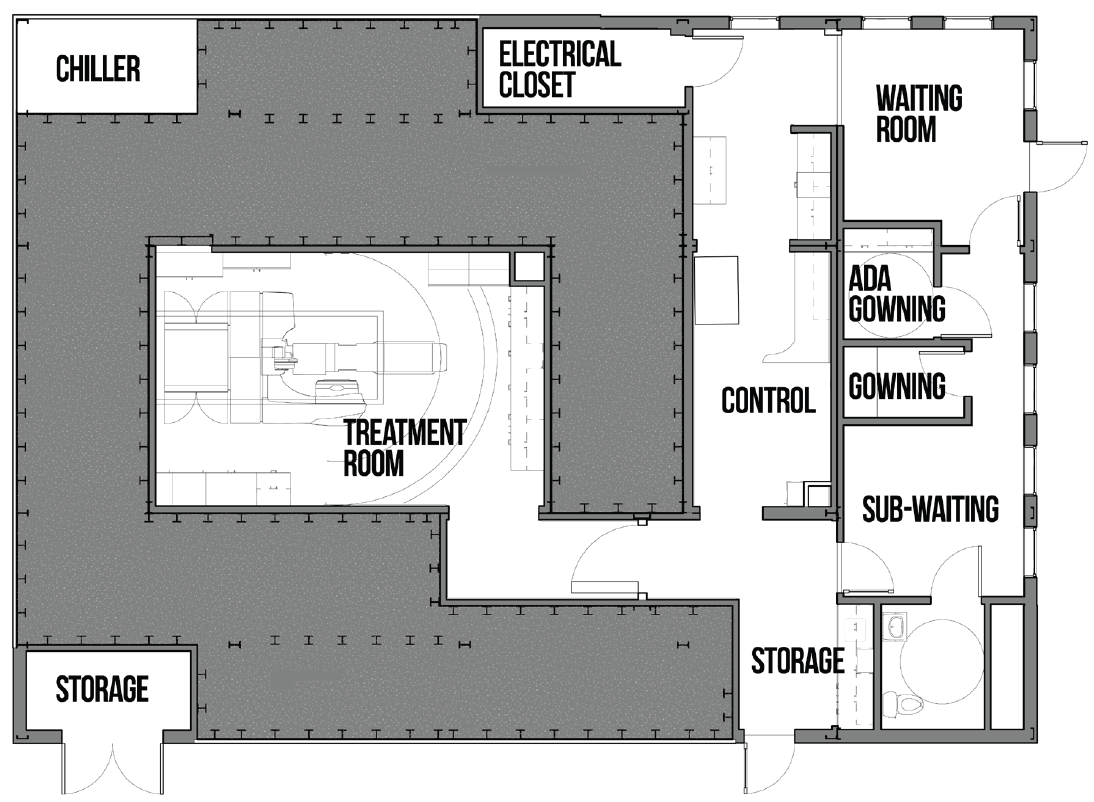

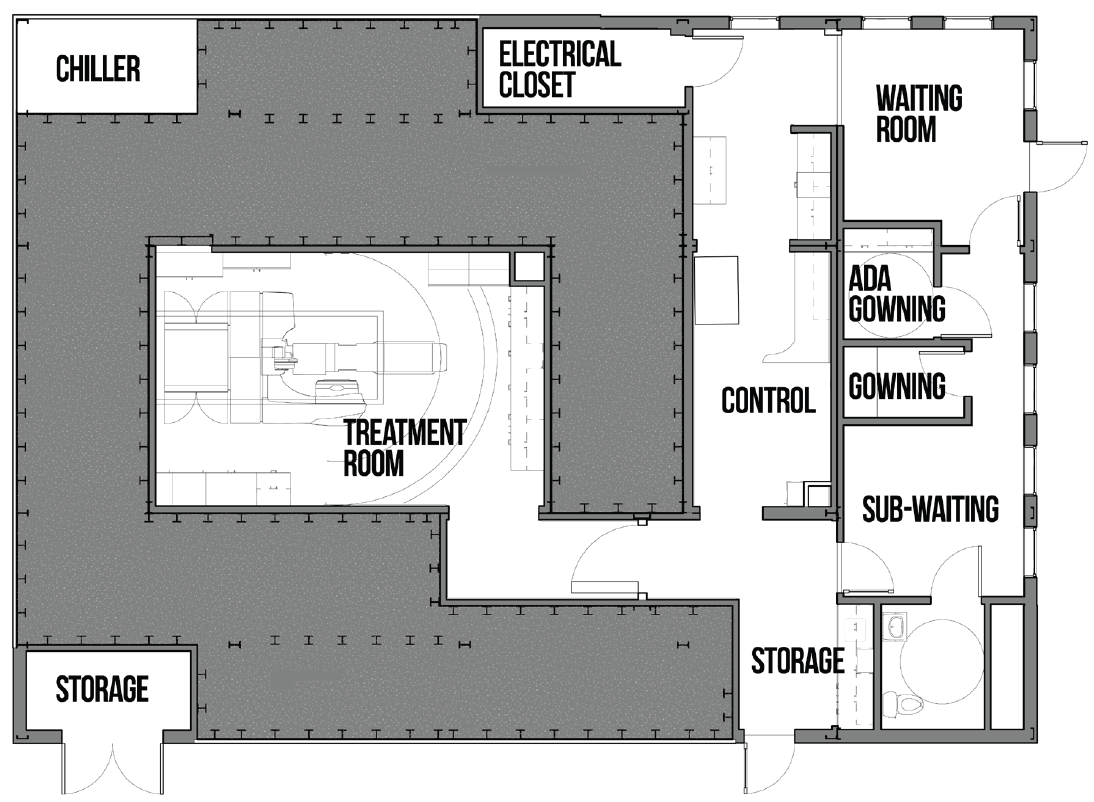

Combined Building Floor Plan Highlights & Achievements

case study summary

A Sunbelt Modular Dealer set out to design a relocatable radiotherapy clinic that could be rapidly deployed to provide advanced cancer treatment where and when it’s needed most.

Whitley Manufacturing partnered with a Sunbelt Modular Dealer to deliver the Temporary Radiotherapy Vault (TRV) — a 1,395 sq. ft. modular clinic and vault built off-site for speed, efficiency, and flexibility. Composed of four primary modules, the facility was completed and operational in just 45 days, including the placement of a pre-commissioned linear accelerator on site.

The TRV was engineered for mobility and longevity, featuring a specialty foundation system requiring no concrete slab — saving over 80,000 pounds of material. Its sleek exterior, clad in wood-grained EcoClad® panels, combines contemporary aesthetics with environmental performance, while the interior offers a welcoming, durable atmosphere designed for patient comfort and repeat relocation.

Building Floor Plan Highlights

case study summary

A Sunbelt Modular Dealer set out to design a relocatable radiotherapy clinic that could be rapidly deployed to provide advanced cancer treatment where and when it’s needed most.

Whitley Manufacturing partnered with a Sunbelt Modular Dealer to deliver the Temporary Radiotherapy Vault (TRV) — a 1,395 sq. ft. modular clinic and vault built off-site for speed, efficiency, and flexibility. Composed of four primary modules, the facility was completed and operational in just 45 days, including the placement of a pre-commissioned linear accelerator on site.

The TRV was engineered for mobility and longevity, featuring a specialty foundation system requiring no concrete slab — saving over 80,000 pounds of material. Its sleek exterior, clad in wood-grained EcoClad® panels, combines contemporary aesthetics with environmental performance, while the interior offers a welcoming, durable atmosphere designed for patient comfort and repeat relocation.